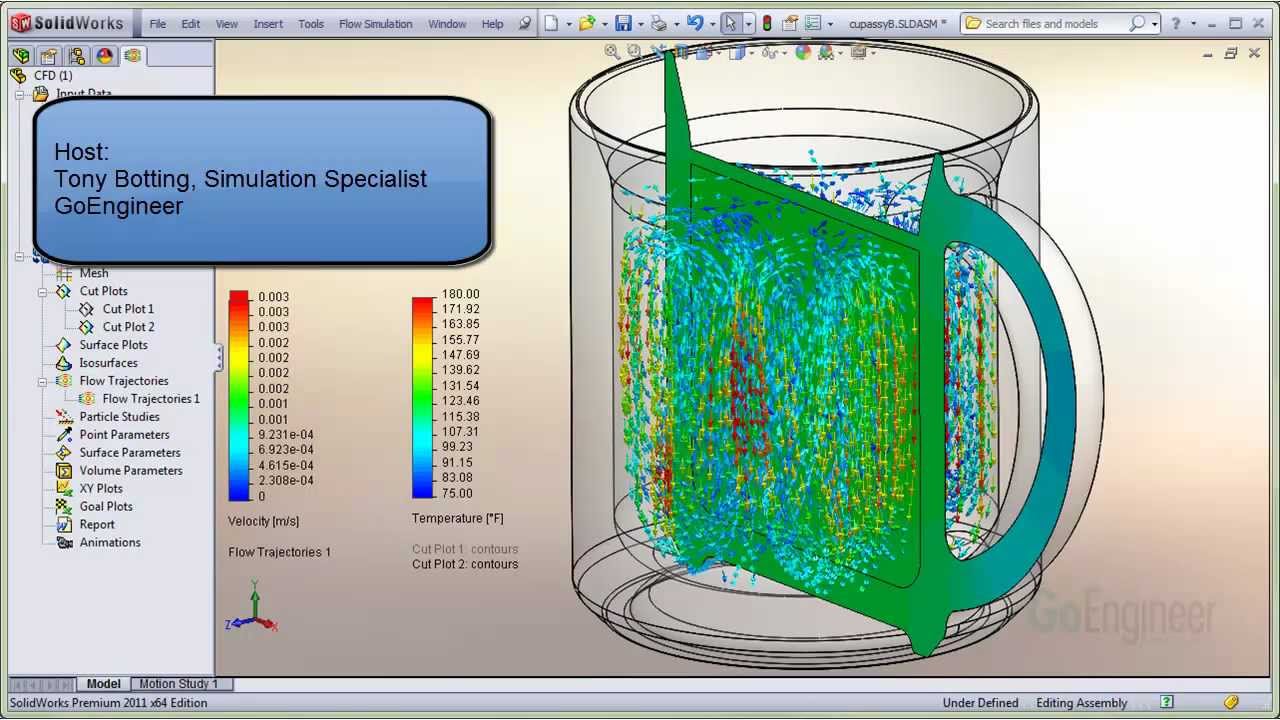

solidworks flow simulation heat transfer

For thermal heat transfer analysis choose SOLIDWORKS Flow Simulation over the Thermal solver in Simulation Professional Part 3 of 3 Meshing. Even if you find your knowledge of SOLIDWORKS.

An Image Of Aerodynamic Analysis Of A Vehicle Wing Mirror That Shows The Pressure Distribution Of Mirror Surface And Velocity Distribution

The heat sink is inserted in the duct by the part of the fins in order to capture the heat flow through the duct.

. Im trying to simulate an assembly with a duct and a heat sink. All you need is a SOLIDWORKS ID or a new or existing 3DEXPERIENCE ID. Heat transfer analysis in the 3D CAD environment.

We are NOT interested in knowing the time it takes to reach this state. Hello Im new in flow simulation. There are two types of heat transfer analyses based on interest in time.

With the exception of very few scenarios when considering a thermal analysis solver for SOLIDWORKS you should choose to use Flow Simulation which is a computational fluid dynamics CFD code. I am doing this in order to see how long it. Next well right-click on Heat Sources and select Insert Surface Source.

Hi all Im wondering if I can let Solidworks ignore heatenergy equations when calculating for flow simulation. As noted above there are three modes of heat transfer. After the simulation is finished I can get the values for the heat transfer coefficient.

For our heat source we. Some of the topics covered include. Time in SolidWorks Flow Simulation.

Tutorials training and watching Internet videos can help but the Flow interface is different and there are many more parameters to consider when analyzing fluid flow and heat transfer. To learn more download our white paper using the form below. Heat transfer issues can be exceedingly difficult and often impossible due to the obstacles.

2 days agoRunning SOLIDWORKS Flow even if you are SOLIDWORKS Simulation users will be a bit daunting. You can apply these settings globally or for assemblies to a. The main 3 reasons why Flow Simulation is the better option will be outlined in a series of three parts.

Ive made a long-form video explaining all of these modes in more detail see link at the bottom so I will only summarize them here in the. Conduction convection and radiation. As you may already know there are three modes of heat transfer.

Im mainly interested in simple flow pattern and the temperature is not really. With the exception of very few scenarios when considering a thermal analysis solver for SOLIDWORKS you should choose to use Flow Simulation which is a computational fluid dynamics CFD code. With an easy-to-use fluid-flow analysis application like SOLIDWORKS Flow Simulation software you will have the tools that you need to solve even the most difficult heat transfer problems while saving time and money in the process.

Flow simulation - Ignore heat transfer Quanyou Shi 9 months ago Open in Forum. I dont define any temperatures nor any heat flows. This allows you to compare design variations quickly to make.

In this tutorial We will learn how to Do heat transfer analysis in solidworks flow simulation. In this type of analysis we are only interested in the thermal conditions of the body when it reaches a state of thermal equilibrium. With integrated CFD you can accurately predict product performance as it relates to fluid flow airflow and aerodynamics as well as heat transfer and cooling.

SOLIDWORKS Flow Simulation gives you powerful fluid flow analysis tools directly in your 3D CAD interface and offers easy automated test setup and quick feedback. SOLIDWORKS Flow Simulation - Animation of Time-dependent Heat. For the selection well choose the four burner faces mentioned earlier.

QuickTips video presented by Tony Botting of GoEngineer. At thermal equilibrium the thermal. Air or liquid flow is a critical part of keeping any electronics properly cooled this video shows how Flow Simulation handles both aspects of such problems.

Learn about developing an animation of heat transfer vs. I have an assembly in Solidworks 2010 and I am trying to simulate heat transfer throughout the component using the Simulation tool. I have been asked a few times about calculating and applying a convection boundary condition for SOLIDWORKS Simulation Thermal analyses because without a CFD software like SOLIDWORKS Flow Simulation convection must be calculated by hand.

This question has a validated answer. This is where computational fluid dynamics CFD with SOLIDWORKS Flow Simulation software comes in. SOLIDWORKS Flow Simulation enables you to run what if scenarios and efficiently analyze the effects of fluid flow heat transfer and related forces on or through components.

Hi all I like to simulate the heat transfer coefficient for a specific flow simulation problem. To start well right click on the project and select Customize Tree. Basically I want to heat the top of the component at 210 C and then allow heat to flow through the component and then radiate to the external atmosphere say at 25 C.

Set the initial temperature of a solid. LM By Lukas Müller 022116. Simulate heat transfer coefficient.

This is an internal analysis with default outer wall condition heat transfer coefficient 7wm2K. Conduction convection and radiation. Equally important it encourages engineers to explore many more what-if scenarios to perfect their designs.

For thermal heat transfer analysis choose SOLIDWORKS Flow Simulation over the Thermal solver in Simulation Professional Part 1 of 3 Conduction. Steady State Thermal Analysis. We will mix hot and cold water in soliworks flow simulation t.

To-use fluid-flow analysis application like SOLIDWORKS Flow Simulation software you will have the tools that you need to solve even the most difficult heat transfer problems while saving time and money in the process. SOLIDWORKS Flow Simulation can improve design productivity and may dramatically reduce the number of physical prototypes needed for testing. Next we need to check the box next to Heat Sources to add it to the tree.

Set additional parameters that control how the analysis resolves the solidfluid interface curved surfaces narrow channels small solid features etc.

Aerodynamics Simulation Virtual Wind Tunnel Using Simscale Aerodynamics Aerodynamics Design Computational Fluid Dynamics

Simulation Of A Water Purification Process In A Maze Channel Reactor Cfd Simulation Water Purification Process Water Purification

Thermofluid Analysis Of A Heat Exchanger Computational Fluid Dynamics Ansys Heat Exchanger

With Its Cfd Analysis Capabilities You Can Simulate Liquid And Gas Flow In Real World Conditions Run What If Sc Computational Fluid Dynamics Fluid Flow Fluid

Ansys Fluent Tutorial Ansys Fluent Tutorial

Introduction To Solidworks Flow Simulation Solidworks Mechanical Design Simulation

Software Cfd Criacao De Simulacoes De Fluidodinamica Cfd Simulation Computational Fluid Dynamics Fluid Dynamics

Easily Simulate Fluid Flow Heat Transfer And Fluid Forces That Are Critical To The Success Of Your Design With Solidworks Flow Simulation Contact 91 Scherma

Heat Exchanger Simulation Heat Exchanger Simulation Cfd Simulation

Flow Simulation Heat Exchanger

Find The Best Global Talent Video Video Ansys Cfd Simulation Simulation

Pin On Computational Fluid Dynamics Cfd

Turbulent Flow Through A Cyclone Separator Https Www Simscale Com Projects Dheiny Turbulent Computational Fluid Dynamics Engineering Projects Fluid Dynamics

Solidworks Flow Simulation Transient Natural Convection Solidworks Simulation Flow Training

Suction Pump Simulation Using Flow Simulation Solidworks Tutorial Solidworks Simulation

Electronic Assembly Cfd Using Solidworks Flow Simulation Conjugate Heat Transfer In 2022 Solidworks Heat Transfer Heat

Solidworks Flow Simulation Transient Manifold Airflow Solidworks Industrial Design Sketch Solidworks Tutorial